Friday, August 14, 2020

Is there a big difference in quality between different brands of power tools such as Dewalt, Ryobi, Milwaukee etc?

Ryobi seems to be mostly aimed at the homeowner market now. Nothing wrong with that, they’ll do the job for 90% of users. Just not great for the few who use their tools constantly.

The rest are all pretty close. This year this brand makes the best of this tool, next year another brand will be better at that tool, but the first brand will make another tool better.

I used to fix tools for Makita, and I already had some corded Makita tools. When I worked there I got into the cordless Makita though, so now I stick with them because of battery interchangeability and because I’m familiar with them. There have been some changes, but you can still use an old tool with a new battery. Also, I know how to fix them, so they last a little longer…like, forever.

The big brands also make homeowner tools…still great tools, but maybe not as powerful or rugged. Those tend to be cheaper, but there’s really nothing wrong with them.

Here’s a little hint for finish carpenters and woodworkers though: You don’t need the big professional drill. The homeowner version will do the job for you.

Framers and deck guys and steel roof guys and metal guys: You need the big professional drill, don’t cheap out.

Pig farmers: No tool is going to work if throw it in the shit pile and when you bring it in to get it fixed nobody wants to work on it.

Why Do Woodworkers Recommend Owning a Drill Press?

A drill press is a crucial tool for each woodworker's search. though woodworkers could also be able to perform several of the drill press's functions with alternative tools, the majority of them notice that these functions square measure easier and faster to accomplish with a drill press.

1. Accuracy

The primary reason why each craftsman ought to have a drill press is accuracy. abundant woodwork involves exactly trained holes, and a drill press is capable of making equally spaced holes of the precise depths, widths, and angles a style demands. A craftsman will clamp a bit of wood firmly into position with the drill press's spindle set to a particular angle relative to the piece of wood. this permits woodworkers to attain the angle of the outlet that they have. A depth-stop mechanically prevents the drilling bit from sinking too way into the piece of wood. These options lead to holes trained accurately for depth and angle, and also the craftsman will simply repeat the holes throughout the piece of wood.

2. Speed

A drill press allows a craftsman to figure additional quickly. By mechanically setting angles and depths, they are doing not have to be compelled to worry concerning operating quite as rigorously to avoid mistakes. The caution that woodworkers need to exercise once exploitation hand-held drills slows them down compared to the automation of a drill press. moreover, drill presses usually have additional powerful motors than hand-held drills do. These motors rotate drill bits additional quickly, leading to quicker drilling.

3. Power

The powerful motors on drill presses additionally save a woodworker's energy as a result of drilling holes needs less effort than it will with hand-held drills. A drill press's powerful motor additionally allows a craftsman to use terribly massive drill bits for drilling wider holes. while not one, golf shot massive holes into a bit of wood is a way additional heavy method.

Drill presses additionally generate power through leverage. The chuck attaches with a taper whose size depends on the shaft. A rack-and-pinion lever lowers the chuck and spindle, serving to the tools drill holes with ease. By harnessing the facility of a drill press, the craftsman will forestall fatigue and work additional with efficiency.

4. functionality

As mentioned on top of, a drill press allows woodworkers to accurately drill angular holes into wood. simply the flexibility to drill at angles is one amongst the benefits of a drill press. It is difficult to make angular holes with hand-held drills and not have the drilling bit slide off the specified path. A drill press is additionally helpful for drilling holes into in an elaborate way formed items of wood, like furnishings legs. this type of practicality makes a drill press helpful in nearly any woodworker's search.

5. versatility

Drill presses are literally versatile machines capable of doing over simply drilling holes. Most operate at variable speeds and square measure able to be fitted with alternative tools, like a spindle smoother or a rotary sanding disc. This makes a drill press helpful for sanding. Attaching a mortise allows a craftsman to bore squares and rectangles into a bit of wood. Moreover, the facility of a drill press makes it capable of drilling holes into metal. this is often a helpful feature since several woodworkers additionally work with metal and incorporate it into their wood items.

6. Safety/Security

One of the foremost vital advantages of a drill press is that the safety and security it provides to woodworkers whereas they work on a bit of wood. The variable speed feature offers woodworkers smart command over the drilling bit, serving to confirm it doesn't break throughout use. A craftsman may use a vice or a clamp to secure a bit of wood to a drill press's table. This prevents the wood from slippery because the craftsman operates the drill press and helps keep the craftsman safe.

Key Points concerning Drill Presses

Being conversant in the advantages of drill presses is one facet of understanding why each craftsman ought to have one among st these machines. the opposite vital facet is knowing however drill presses bestow these advantages onto woodworkers. Being tuned in to these key points helps woodworkers opt for drill presses appropriate for his or her retailers.

Is today's wood softer than 40 years ago?

I don't know as that is a general statement that can be made. Whether it is softer or not I don't know, but construction Lumber certainly isn't as strong as in the past. Most of that has to do with sustainable practices in the lumber industry. Spruce, Pine, Fir (often listed as SPF in lumber yards) is what is generally used for construction. The stuff is grown fast and cut early.

Below is a picture of two pieces of two by four. The top one is a piece of original stud that I took out of my 1905 Farmhouse when I was doing some remodeling. The bottom one is a piece that I purchased at Home Depot. The difference in growth rings is amazing. That's what makes the difference.

Is it okay to attach a circular saw blade to my power drill

Do not attempt to cut wood with a circular saw blade attached to a drill. It will be very dangerous and work very badly if at all.

The suggestion to get a handsaw is correct. A short utility saw will do but will be more work. A longer rip saw will do the job better and faster but the utility saw will be more versatile for future projects.

A Japanese Ryoba saw would also work, many find it easier as it cuts on the pull stroke, and it has both crosscut and rip edges for even better versatility.

For reference this is a utility saw…

This is a rip saw…

And this is a Ryoba…

My dad once told me that real wood workers don't use nails, is that true? If so, why?

I guess it depends on how you’re defining “real wood workers.” In general, there’s probably good evidence that most carpenters (whom I would consider “real wood workers”) use nails. Nailing wood together is a quick and reliable way to join pieces of wood together and commonly used. While possible, I can’t imagine building a backyard deck without nails.

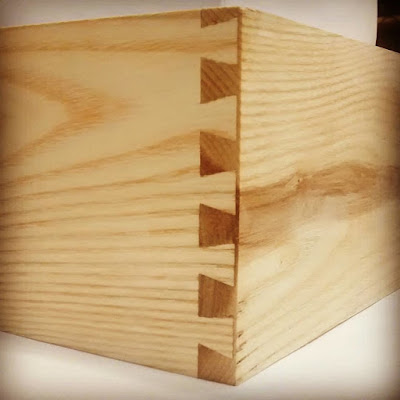

However, your father may have been speaking more of wood craftsmen/craftswomen, people who design their own pieces. Such a person would have the skill of joining wood with joints, cuts in the wood that enable wood pieces to fit together and hold fast. This kind of work requires a lot of precise cuts and takes time to do well. There’s a wide breadth of joint types, including the “mortise and tenon joint” and “finger joints”/”comb joints” pictured below:

Mortise and Tenon Joint

Comb Joints

Biscuit Joint

Bridle Joint

Dovetail Wood Joint

Why would a wood worker use joints instead of nails or glue? Here are a few reasons:

- A nail-free piece shows off a woodworker’s skill and talent

- Nails can be seen in the end result of a piece and can distract from the beauty of the wood; joints can be internal and invisible or visible but attractive

- A piece using joints can be assembled without tools and extra pieces.

- Similarly, such a piece can be dismantled without destroying the individual pieces.

Subscribe to:

Comments (Atom)